Dental devices must be manufactured with the highest level of precision and sterility. Components such as dental scaler housings, suction tips, medicament cartridges and orthodontic tool bodies must form perfect joints that withstand pressure, fluid exposure and sterilization processes.

Traditional bonding methods like gluing introduce chemical residue, weaken under moisture and fail to deliver repeatable precision. Mechanical fitting creates gaps and risks internal contamination.

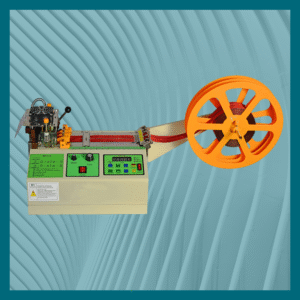

The altrAsonix Ultrasonic Plastic Welding Machine for Dental Device Plastic Parts uses ultrasonic vibration to fuse thermoplastic components at the molecular level, creating a permanent, sterile and uniform weld. This makes the machine suitable for dental consumables, handpiece covers, diagnostic accessories and orthodontic products.

The following guide provides essential material, weld-joint and engineering insights for dental device manufacturers.

Plastic Welding Guide for Dental Device Components

Which Plastics Can Be Welded?

Dental components are typically made from ABS, PP, PC, PMMA and high-grade medical polymers. These materials respond well to ultrasonic welding because they melt and re-solidify cleanly under controlled energy.

Elastomers and thermosets cannot be welded.

Common Weldable Plastics and Their Behavior

ABS – Ideal for ergonomic handpiece housings

PP – Good for disposable dental tips

PC – Used for transparent and load-bearing parts

PMMA – Clear but brittle under pressure

PE – Weldable with proper control

PVC – Limited use in oral-care devices

Dental devices commonly combine ABS, PC and PP depending on functionality and load requirements.

Factors Influencing Weld Strength

Melting Temperature

Higher temperature plastics need stronger amplitude and weld power.

Flow Characteristics

Better melt flow forms stronger weld seams.

Elastic Modulus

Rigid plastics transfer ultrasonic energy more efficiently.

Damping Behavior

Controls heat generation within thin dental parts.

Joint Design for Dental Device Assembly

Basic Flat Joint

Used for simple covers and caps.

Step Joint

Ensures alignment and improves sealing for dental handpieces.

Tongue and Groove Joint

Used for airtight suction tips and applicator chambers.

Mash Joint

Ensures uniform melt for fine-wall plastic segments.

Joint With Inserted Seal

Used where internal valves or medicament membranes exist.

Each joint design increases reliability and enhances user safety.

Key Features

• Suitable for PP, ABS, PC and medical-grade polymers

• Airtight welds for dental chambers and suction components

• Zero chemical residue or adhesive contamination

• Suitable for sterile and hygienic manufacturing environments

• High accuracy for fine and delicate dental parts

• Long-life aluminium ultrasonic horn

• Fast cycle time for production batches

• Stable performance with repeatable weld quality

Technical Specifications

(Dental parts are small to medium components → 20 kHz / 2000W Analog recommended)

| Parameter | Details |

|---|---|

| Model | UPM-20K-2000W-ANALOG |

| Frequency | 20 kHz |

| Power Output | 2000W |

| Welding Mode | Time / Manual |

| Rectifier Type | Analog |

| Input Voltage | AC 220V |

| Operation Type | Manual |

| Weight | Approx. 90 kg |

| Used For | Small/medium PP/ABS/PC dental device components |

Material Compatibility

| Material | Compatible | Notes |

|---|---|---|

| ABS | Yes | High precision & stability |

| PP | Yes | Good chemical resistance |

| PC | Yes | Transparent and durable |

| PMMA | Partial | Brittle under pressure |

| PE | Yes | Limited use |

| PVC | Limited | Controlled welding |

| PA | No | Not weldable |

| POM | No | Not suitable |

Detailed Product Applications

The altrAsonix Ultrasonic Plastic Welding Machine for Dental Device Plastic Parts is ideal for producing:

• Dental scaler housings

• Suction tip plastic components

• Dental procedure applicator housings

• Orthodontic device parts

• Dental impression device covers

• Liquid medicine cartridge assemblies

• Dental diagnostic device enclosures

• Disposable dental accessory components

These components require precision, safety and sterility, making ultrasonic welding the preferred method.

Reviews

There are no reviews yet.